An AC motor in which the rotation period is exactly the same as an integral number of AC cycles; which rotor rotates with the same speed as the rotating magnetic field produced by the electric supply is known as the synchronous ac motor.

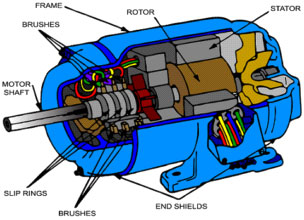

The two basic components of every motor are the stator and the rotor. The stator of synchronous motors same as the stator of induction motor. The stator is the stationary part of the motor. voltage is generated in the armature winding which is carried by the stator. Various parts of the stator are

stator frame– stator frame is the outer body that is made of cast iron. its main function is to protect the inner parts of the motor. it contains a wrapper plate that is attached to circumferential ribs and keyboards.

stator core – stator core is made up of silicon steel material. To provide an easy path for the magnetic lines of force and to house the stator winding is the function of the stator core.

stator windings– stator winding is the winding that is installed on the stator. stator winding is made of copper. The main function of the stator winding is to produce a rotating magnetic field.

cooling arrangement – in the cooling arrangement of the stator, water is contained in a closed-loop system that cools the copper stator bars in water-cooled generators.

The rotor is the rotating part of the motor. There are two types of the rotor in synchronous motor and they are salient pole rotor and the non-salient pole rotor. The nonsalient rotor has six poles and when a large number of poles is needed salient pole rotor is used.