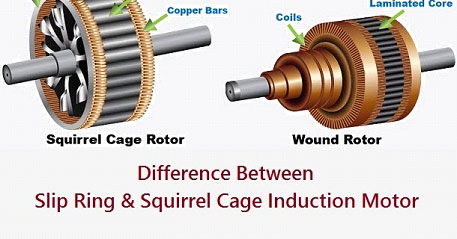

| squirrel cage motor | slip ring motor |

| An AC induction motor in which squirrel cage rotor is used is called as squirrel cage motor. | An AC induction motor in which slip ring rotor is used is called as slip ring motor, it is also known as phase wound motor |

| The slots of the rotor are not parallel, but are skewed. | Rotor have a Cylindrical laminated core with parallel slots and each slot consist one bar. |

| Construction is very simple and it is cheap as compared to slip ring induction motor. | Construction is complicated due to the presence of slip ring and brushes and because of slip ring and brushes the motor is more costly. |

| The rotor consists of rotor bars which are permanently shorted with the help of end rings, so it is not possible to add external resistance. | The rotor is similar to the stator winding. Using slip ring and brushes rotor resistance can be easily added. |

| Staring torque is low and cannot be improved. | Due to the presence of the external resistance high starting torque can be obtained. |

| It required Less maintenance. | Frequent maintenance is required due to the presence of brushes. |

| It is the most popular type of AC motor and it is very commonly used in industries because it is very cheap, robust, efficient, and reliable. | slip ring motor has very little application in industries and they are Rarely used 5% to 10% slip ring motors in industries |

| Copper losses is less and hence the efficiency and power factor is high | Copper losses are high and hence the efficiency and power factor is low. |

| Speed control is not possible. | Speed control is possible by rotor resistance method. |

| They are used in lathes, drilling machine, fan, blower printing machines etc. | They are used where the starting torque is high I.e in hoists, cranes, elevator etc . |