The industrial internet of things (IIoT) enables engineers to constantly monitor and control equipment, products and processes across long distances. However, when thousands of IIoT sensors periodically require fresh batteries, maintaining the system can become untenable.

Long-range wireless charging technology, including radio frequency (RF) harvesting, collects energy from wireless signals. IIoT sensors outfitted with this charging technology are more self-sustaining.

Nikola Labs, an ANSYS Startup Program member, is trying to create a world without wires. Thanks to ANSYS HFSS, the startup is one step closer to making that dream a reality.

“We are installing IIoT sensors that monitor the vibration and temperature of industrial machines,” says Brock DeLong, RF engineer at Nikola Labs. “Many types of industrial equipment aren’t outfitted with monitoring technology. By installing these sensors, equipped with long-range wireless charging technology, our customers can keep track of the health of their machines.”

Long-Range Wireless Charging Technology Can Operate on 31.6 µW

When Nikola Labs optimizes its wireless charging technology it faces two significant constraints:

- RF harvesting technology is bound by Federal Communications Commission (FCC) rules that limit the amount of energy that is emitted.

- Large industrial equipment — which most facilities cannot move — can cause signal loss.

Therefore, when Nikola Labs optimizes its designs to deliver power effectively, it focuses on the transmitter and the receiver on the IIoT sensor. Nikola Labs also optimizes the power budget so that the receiver system can run on low power.

Roland Tallos, chief engineer at Nikola Labs, says, “We’ve miniaturized our RF to direct current (DC) harvesting and battery management circuitry into a single package, and we maximize the antenna’s performance based on the constraints of our customers.”

He adds, “It’s all about how efficiently you can receive power within a given environment. This dictates how many readings an IIoT sensor can take in a day. Since our system will operate on as little as 31.6 µW, we have a leg up on the competition.”

Another advantage Nikola Labs has over its competition is that its RF harvesting chip is exceptionally small compared to other receivers. This means that the IIoT sensor will be able to fit into smaller spaces.

Simulation Helps Engineers Design Long-Range Wireless Charging Technology

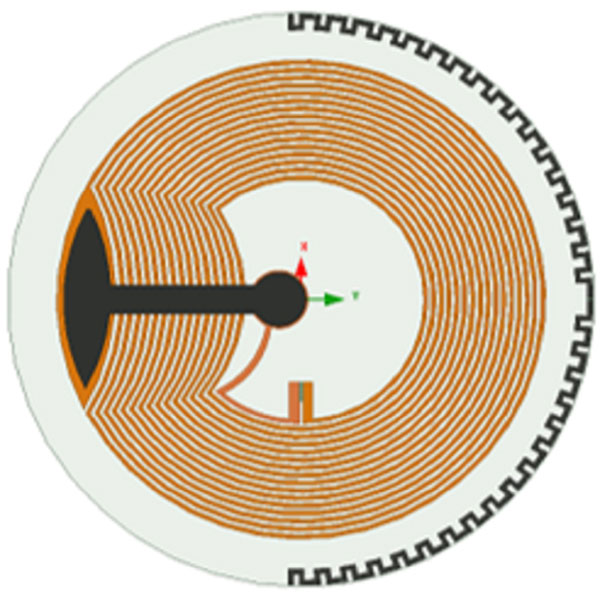

An RF transmitter propagates the wireless signal while the receiver captures it and changes it into DC energy.

DeLong says, “For us to maximize the operational distance and power delivered, key factors of our antennas such as the gain, impedance match and polarization needed to be optimized in HFSS.

“Without HFSS, we would have to rely on other organizations to make the design, or stick with an off-the-shelf solution,” says DeLong. “Simulation allows us to test our design’s geometry and material. It also helps us understand the radiation pattern.”

Nikola Labs can also use HFSS to simulate the environment in which the RF harvester and IIoT sensor will operate. This simulation helps Nikola Labs understand the power budget for their receivers.

Testing the power budget and a receiver’s design using physical prototypes would be much more expensive and time-consuming. Simulation helps Nikola Labs stay on budget and on a tight design schedule.