There are mainly two types of AC motors,the synchronous motor and the induction motor.

Synchronous motor

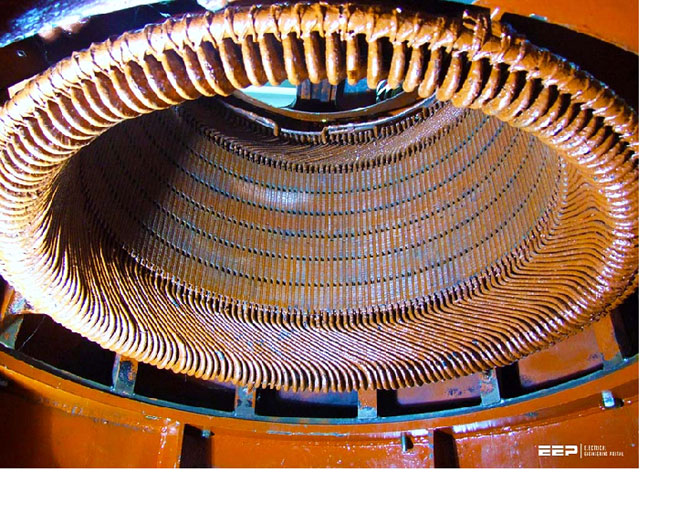

Synchronous motor is the AC motor in which the rotor will rotate synchronously with the rotating magnetic field produced by the electrical supply. in a simple words, it is a type motor in which the speed of the rotor is same as the speed of the revolving field in the machine. in synchronous motor, the stator is similar to that of induction motor.

There are two types of synchronous motors. the motors are differentiate on how the rotor is magnetized: non-excited and direct-current excited.

Non-excited motors

In non-excited motors, the rotor is made of steel, a high-retentivity steel such as cobalt steel. These are manufactured in permanent magnet, reluctance and hysteresis designs.

- Permanent magnet motor

To create a constant magnetic field a permanent-magnet synchronous motor use a permanent magnets which is embedded in the rotor. The stator windings are connected to an AC supply which produce a rotating magnetic field. the rotor poles lock to the rotating magnetic field at synchronous speed. since 2000,Permanent magnet motors have been used as gearless elevator motors. PMSM are also known as line-start or self-starting PMSMs. Direct torque control and field oriented control are used to control Permanent magnet synchronous motors.

- Reluctance motors

A reluctance motor is a type of electric motor that induces non-permanent magnetic poles on the ferromagnetic rotor. The rotor does not have any windings. through magnetic reluctance it generates torque .Because of their high power density at low cost, reluctance motor make them attractive for many applications.

- Hysteresis motors

A synchronous motor which have cylindrical rotor and works on hysteresis losses induced in the rotor of hardened steel with high retentivity is known as Hystersis motors. It is a single phase motor.its rotor is made of ferromagnetic material with non magnetic support over the shaft.

DC-excited motors

At the rear of the machine the exciter can be clearly seen. they are usually made in larger in size that is larger than about 1 horsepower or 1 kilowatt. These motors require direct current (DC) supplied to the rotor for excitation. This is most straightforwardly supplied through slip rings, but a brushless AC induction and rectifier arrangement may also be used. A separate DC source or a DC generator is directly connected to the motor to supply direct current.